There are three CNC machines on market that are designed specifically for the manufacturing of tools and leading the market presently; these are the Rollomatic Laser 510 femto and the EWAG Whatchamacallit, and the DMG MORI Lasertec 50 PrecisionTool femto.

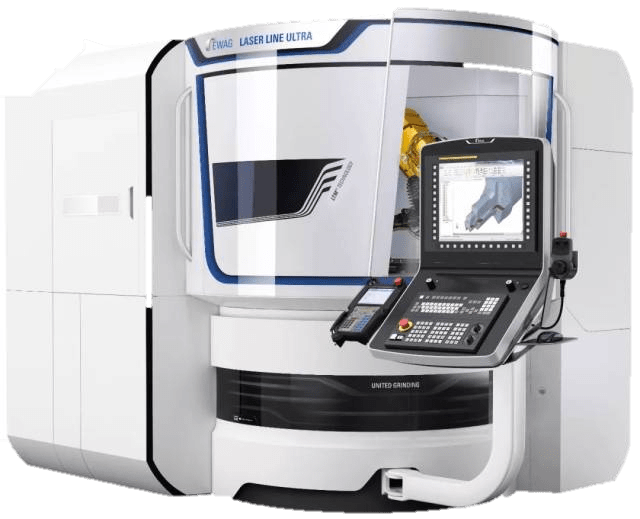

EWAG LASER LINE ULTRA

The EWAG machine is the only picosecond laser on this list; th

EWAG also offer another machine, the LASER LINE PRECISION that is a comparably compact machine that is useful for cutting diamond tooling, and is notably cheaper than the ULTRA. The ULTRA is suitable for diamond and carbide, cermet ceramic and CBN.

Rollomatic Laser 510 femto

The Rollomatic LaserSmart 510 Femto is arguably the benchmark for femtosecond laser tool production. The femtosecond regime (<400 fs pulse width) allows for true athermal ablation, meaning no recast layer or microstructural damage—ideal for maintaining cutting-edge integrity in diamond and carbide tooling.

Rollomatic’s integration between its laser and conventional grinders also stands out: the same tool library can be shared between grinding and laser systems, simplifying hybrid production. The 510 Femto can also apply functional surface textures—micro-grooves or dimples—to control chip flow or improve coolant access directly on the tool flank or rake face.

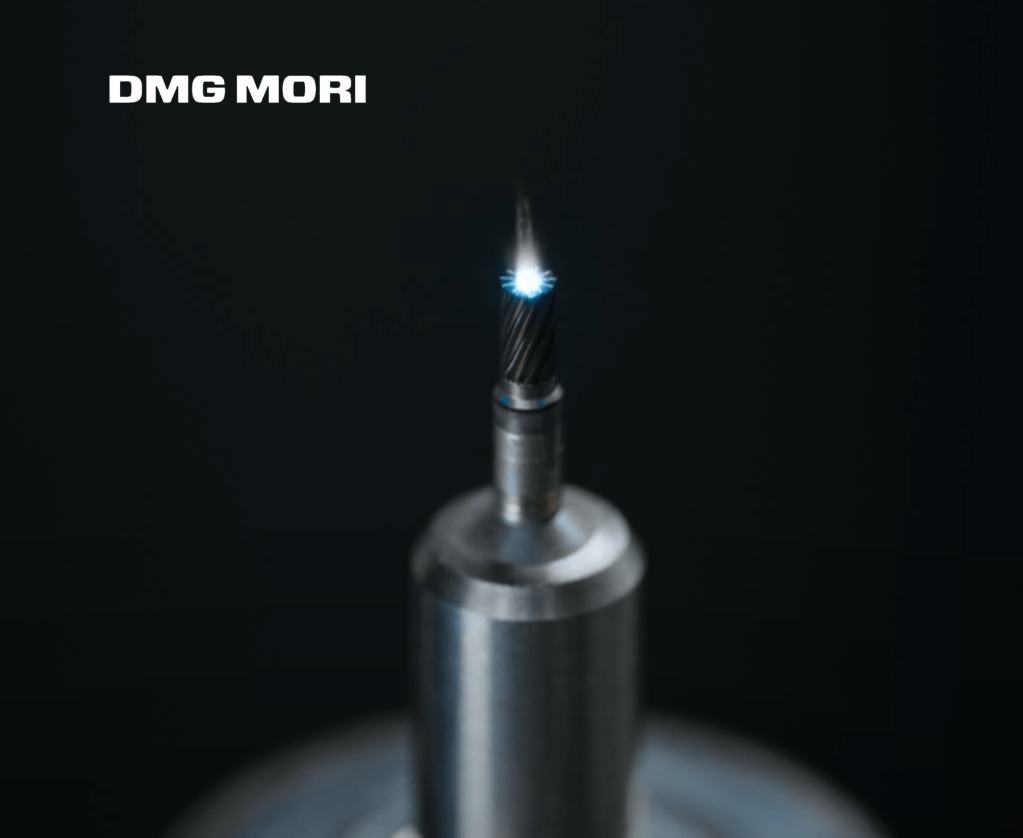

DMG Mori Lasertec 50 PrecisionTool femto

DMG MORI’s Lasertec 50 PrecisionTool Femto is another femtosecond-class system aimed squarely at the high-end tool manufacturing market. It combines the precision of a five-axis machining center with a fully enclosed laser workstation, using a 400 fs infrared source for ultrafast ablation.

DMG MORI emphasizes flexibility: the Lasertec 50 can handle tool diameters from micro-drills (<0.5 mm) to large indexable inserts, with integrated in-machine measurement for closed-loop edge verification. The company has demonstrated the system machining carbide end mills and CBN inserts with surface finishes down to Ra < 0.2 µm—achievable without any post-polishing.

However, there are other players in the game. Household CNC names such as GF (now under United Grinding) and KERN, as well as laser OEMs such as Coherent, Lasea and Oxford Lasers all offer competitive and flexible multiaxis CNC machines that could, in theory, be used for tool manufacturing. These platforms offer more flexibility and modularity than purpose-built tool lasers, which could appeal to research labs or specialty toolmakers who value configurability over turnkey throughput.

Where It’s Heading

Laser micromachining is redefining how cutting tools are made. Instead of physically grinding or brazing, tool edges and chip breakers can be written in light, with features controlled to the micron. In the near term, expect a rise in hybrid tool manufacturing, where grinding establishes bulk geometry and laser finishing defines functional edges, textures, and coatings.

Longer term, the vision is a fully digital workflow—no wheels, no coolant, no contact—where every facet of the tool, from cutting edge to rake microtexture, is designed and produced algorithmically.