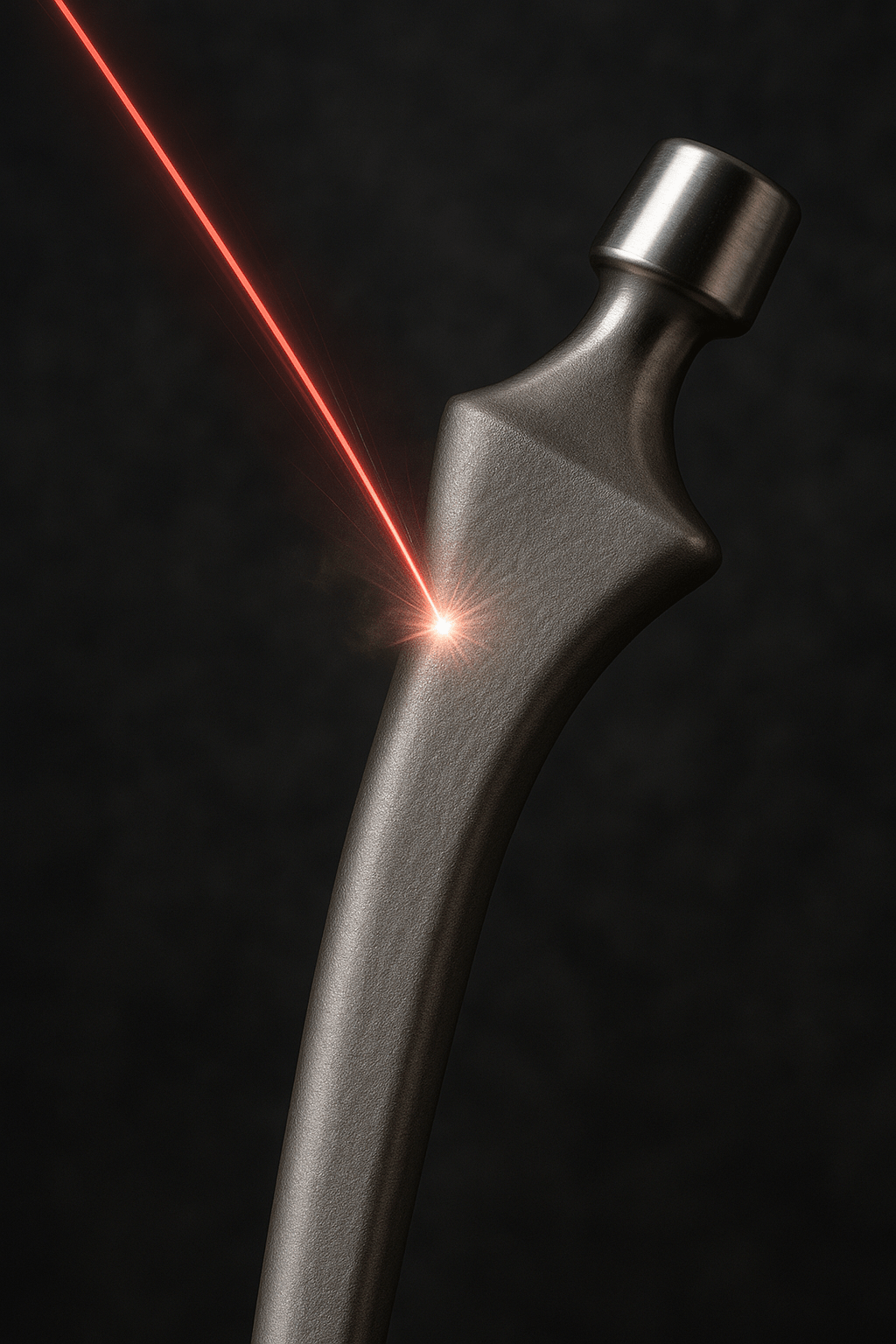

Femtosecond laser texturing is advantageous for many reasons in the context of modifying orthopaedic implants. Perhaps the most talked about in the community is enhanced osseointegration via design of a bespoke surface, achieved with the high control via femtosecond laser surface texturing.

There are, however, other ways to enhance implants mechanically, including increasing hardness, tensile strength and fatigue strength. In the following, we’ll discuss one specific example, namely the increase in fatigue strength via shock peening. Instead of peening with a conventional material, we’ll look at using a femtosecond laser instead, which can impart compressive stresses without a physical media or taping which is required for longer pulse length peening.

Femtosecond laser shock peening adapts a familiar idea from aerospace—use a laser-driven shock to plastically compress the surface—but swaps long or nanosecond pulses for ultrafast pulses. The shorter pulse duration minimizes heat input and melting, so you can introduce near-surface plasticity without the collateral damage that sometimes follows conventional laser processing. For load-bearing orthopaedic materials, that matters: fatigue cracks often start at or just below the surface, and corrosion can accelerate where passive films are weak. If we can harden the first micron and encourage a stable passive layer, we buy time against both failure modes.

A clear example comes from Wang et al. (ACS Applied Bio Materials, 2021), who applied fs-LSP to WE43 magnesium—a biodegradable alloy relevant to temporary fixation devices. They explored how processing choices—power density, an absorbing layer, and a confining medium—translate into surface state. An inexpensive combination (black tape as the absorber, quartz as the confining layer) at ~28 GW cm⁻² produced the best overall outcome: higher hardness, slower corrosion, and markedly improved tribocorrosion behavior in a physiologic saline at 37 °C. Mechanistically, transmission electron microscopy showed a dense dislocation structure within roughly the top micron, not wholesale grain refinement. Finite-element simulations and diffraction suggested that residual stresses do form but are shallow; in this regime, the dislocation density seems to carry most of the benefit. Practically, hardness increased by ~23%, and the total volume loss under tribocorrosion dropped by ~48% versus untreated WE43. Those numbers are meaningful for a degradable implant that must survive early mechanical loading while it’s still needed and then disappear on schedule. www1.phys.vt.edu

What does this imply more broadly for orthopaedics? First, fs-LSP is fundamentally a stress- and defect-engineering tool. On titanium alloys (permanent implants) you’d expect similar crack-initiation delays and potentially improved fretting wear at interfaces such as taper junctions, but the depth and magnitude of compressive residual stress may be less than with nanosecond LSP; process windows will need tuning if deep compressive layers are the priority. On bio-magnesium (temporary implants), the Wang study highlights a second mechanism that is just as important: faster, more uniform repassivation during sliding and abrasion. The high dislocation density appears to accelerate passive film re-formation, which in turn stabilizes corrosion kinetics under load—useful in vivo where micromotion is unavoidable.

There are trade-offs. Femtosecond systems bring tighter spot sizes and lower thermal budgets, but throughput and area coverage must be reconciled with production economics. The shallow affected depth may be a feature (biodegradables) or a limitation (deep-rolled tibial stems). And, as always with peening, process variability (energy coupling, overlap, confinement) maps directly onto property variability; the absorber-plus-confinement detail in Wang et al. underlines how practical fixtures can make or break outcomes.

Still, the direction is promising. If your goal is to harden just enough of the surface to slow crack initiation, dampen wear, and keep corrosion in check—without re-machining or heavy thermal input—fs-LSP offers a controllable way to do it, and it integrates naturally with other surface steps (marking, texturing, coatings) common in implant lines. For biodegradable systems in particular, the combination of modest hardening and enhanced repassivation is exactly what we want: strong at the start, forgiving as it fades. www1.phys.vt.edu

Reference

W. Wang et al., “Enabling High-Performance Surfaces of Biodegradable Magnesium Alloys via Femtosecond Laser Shock Peening with Ultralow Pulse Energy,” ACS Applied Bio Materials 4 (2021) 7903–7912.